I still remember the day I realized that a Workshop Dust Collection System was not just a luxury, but a necessity for my own workshop. I was in the middle of a project, surrounded by a cloud of dust and debris, when I stumbled upon a simple truth: a good dust collection system is not just about keeping your workspace clean, it’s about protecting your health and improving your work quality. The common myth that dust collection systems are only for large-scale industrial operations is just that – a myth. In reality, any workshop, no matter the size, can benefit from a well-designed Workshop Dust Collection System.

So, what can you expect to learn from this article? You’ll get honest, no-hype advice on how to design and implement a Workshop Dust Collection System that meets your specific needs. We’ll cover the basics of dust collection, including key components and installation tips, as well as some more advanced techniques for optimizing your system’s performance. By the end of this guide, you’ll be equipped with the knowledge and confidence to take control of the dust in your workshop and start creating cleaner, safer, and more efficient projects.

Table of Contents

Project Overview

Total Time: 4 hours 30 minutes

Estimated Cost: $200 – $500

Difficulty Level: Intermediate

Tools Required

- Circular Saw ((for cutting lumber))

- Drill Press ((for precise hole drilling))

- Jigsaw ((for curved cuts in ductwork))

- Impact Wrench ((for tightening duct clamps))

- Tape Measure ((for measuring workshop and duct runs))

- Level ((for ensuring proper installation))

- Wire Brush ((for cleaning ducts and fittings))

Supplies & Materials

- 6 inches x 4 feet ductwork ((for main duct runs))

- 4 inches x 10 feet ductwork ((for branch lines))

- Dust Collection System Unit ((central unit with motor and filter))

- Duct Clamps ((for securing ducts to fittings and walls))

- Hangers and Straps ((for suspending ducts from ceiling))

- Y-Fittings and Elbows ((for directing airflow and changing direction))

- Blast Gates ((for controlling airflow to different machines))

- 2-in x 4-in lumber ((for building duct supports and hangers))

- Wood Screws ((for assembling supports and hangers))

- Duct Tape ((for sealing gaps and joints in ductwork))

Step-by-Step Instructions

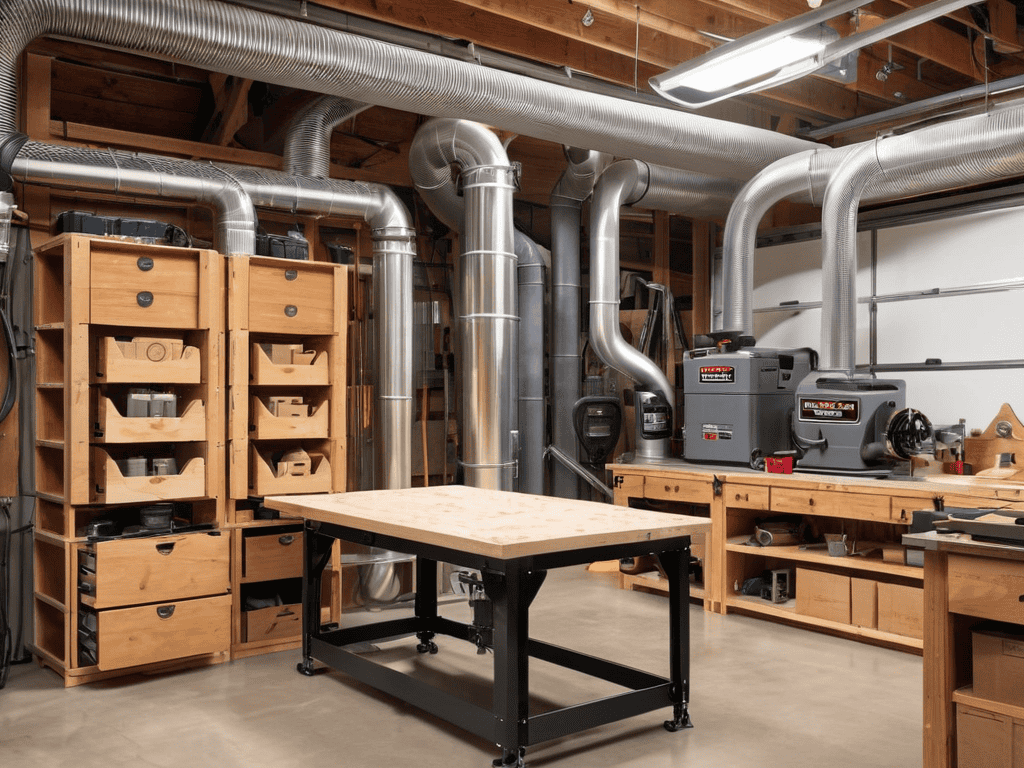

- 1. First, assess your workshop to determine the best location for your dust collection system. Consider the layout of your workspace, the location of your power tools, and the path of least resistance for the ductwork. You’ll want to place the system in a central location to minimize the amount of ducting needed.

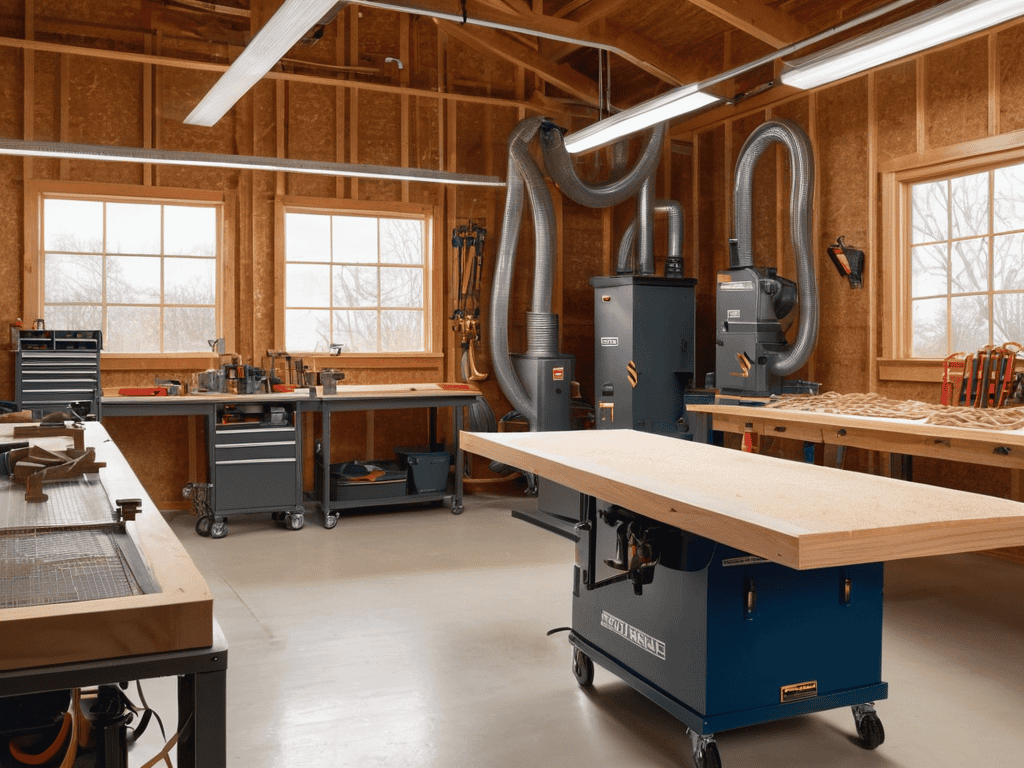

- 2. Next, choose the right equipment for your dust collection system. This includes a dust collector, ducting, fittings, and blast gates. Make sure to select equipment that is compatible with each other and suitable for your specific workshop needs. Consider factors such as horsepower, CFM, and filtration efficiency.

- 3. Now, design your ducting layout to ensure efficient airflow and minimal restrictions. Use a combination of straight ducts, elbows, and tees to create a network that reaches all areas of your workshop. Be sure to include blast gates to isolate different sections of the workshop and prevent dust from circulating back into the air.

- 4. After designing your layout, install the ducting according to your plan. Start by connecting the dust collector to the main duct, then work your way out to the individual tools and machines. Use fittings and clamps to secure the ducting in place, and make sure all connections are airtight to prevent leaks.

- 5. Once the ducting is installed, add blast gates and fittings as needed to control airflow and direct dust to the collector. Blast gates should be installed at each tool or machine to allow for isolation and to prevent dust from entering the ducting when not in use. Fittings such as elbows and tees should be used to change direction or split the ducting.

- 6. Next, connect your tools and machines to the dust collection system. This may involve installing adapters or hoses to connect the tools to the ducting. Make sure all connections are secure and airtight to prevent dust from escaping.

- 7. Finally, test and fine-tune your dust collection system to ensure it’s working efficiently and effectively. Turn on the system and check for leaks or restrictions in the ducting. Make adjustments as needed to optimize airflow and dust collection. Regularly maintain your system by cleaning or replacing filters, checking for blockages, and ensuring all connections remain secure.

Taming Workshop Dust Collection System

To take your dust collection to the next level, consider investing in industrial dust collection systems that are designed to handle heavy-duty workshop demands. These systems often come with advanced features such as automated dust collector filter maintenance, which can save you time and hassle in the long run. By keeping your filters clean and well-maintained, you can ensure optimal performance and woodshop dust control solutions that actually work.

In smaller workshops, it can be challenging to find space for a dedicated dust collection system. However, there are many small shop dust collection ideas that can help you make the most of your available space. For example, you can opt for a compact central vacuum system design that can be easily installed and hidden from view. This can be a great way to improve workshop air quality improvement without sacrificing valuable floor space.

As you’re working on perfecting your workshop’s dust collection system, it’s essential to stay up-to-date with the latest techniques and technologies. I’ve found that attending workshops and seminars can be a great way to learn from experienced professionals and gain valuable insights. For instance, I recently came across a fantastic resource, t4m sydney, which offers a wide range of workshops and training programs focused on industrial dust control and air quality management. By taking advantage of these opportunities, you can gain a deeper understanding of how to implement effective dust collection strategies and create a safer, healthier work environment.

By implementing these strategies, you can create a cleaner, healthier, and more productive workshop environment. Remember to always prioritize dust collector filter maintenance to get the most out of your system. With a little creativity and planning, you can tame the dust demon in your workshop and enjoy a safer, more efficient workspace.

Industrial Dust Control Simplified

Industrial dust control doesn’t have to be overwhelming. By breaking it down into manageable parts, you can create a system that works for you, not against you. Start by identifying the main sources of dust in your workshop – is it your table saw, sanders, or perhaps your drill press? Once you’ve pinpointed the culprits, you can start implementing targeted solutions, such as installing dust ports or using a shop vacuum with a HEPA filter.

This simplified approach allows you to tackle dust control one step at a time, making it feel less daunting and more achievable. By focusing on one area or machine at a time, you can create a cleaner, healthier workspace without feeling overwhelmed by the task.

Woodshop Air Quality Hacks

To breathe easy in your woodshop, consider a few air quality hacks. A HEPA air purifier can be a lifesaver, capturing 99.97% of particles as small as 0.3 microns. This means fewer dust particles floating around, making your workspace safer and cleaner. Regularly cleaning your tools and equipment also helps reduce dust buildup.

Proper ventilation is also key. Open windows and doors to let fresh air in, and invest in a ventilation system if possible. This will help remove stale air and prevent dust from recirculating. By implementing these simple hacks, you can significantly improve the air quality in your woodshop, making it a healthier and more enjoyable space to work in.

Dust Busting Essentials: 5 Tips to Supercharge Your Workshop Dust Collection System

- Upgrade to a cyclone dust collector for improved efficiency and reduced clogging

- Regularly inspect and maintain your ductwork to prevent leaks and optimize airflow

- Implement a multi-stage filtration system to capture even the finest dust particles

- Strategically position your dust collection outlets to maximize coverage and minimize dead spots

- Schedule periodic thorough cleanings of your dust collection system to prevent buildup and ensure peak performance

Key Takeaways for a Cleaner Workshop

Dust collection systems are not just a luxury, but a necessity for maintaining a clean and healthy workshop environment, reducing the risk of respiratory issues and improving overall productivity

By implementing a few simple woodshop air quality hacks, such as regular filter cleaning and strategic ductwork design, you can significantly enhance the performance of your dust collection system

A well-designed dust collection system can be a game-changer for your workshop, allowing you to focus on your projects without the distraction and hazards of excessive dust and debris

The Dust Collection Truth

A workshop dust collection system is not just a tool, it’s a guardian of your health, a defender of your sanity, and a silent partner in your creative journey – treat it as such and it will reward you with cleaner air, safer projects, and a clearer mind.

Joe Workshopper

Conclusion

In conclusion, setting up a workshop dust collection system is a crucial step in maintaining a clean and safe workspace. We’ve covered the essential steps to get you started, from choosing the right equipment to implementing woodshop air quality hacks. By following these guidelines, you’ll be well on your way to minimizing airborne particles and keeping your workshop dust-free. Remember, a good dust collection system is not just a luxury, but a necessity for any serious woodworker or DIY enthusiast.

As you embark on this journey to tame the dust demon in your workshop, keep in mind that it’s an ongoing process. It requires patience, dedication, and a willingness to adapt to new techniques and technologies. But the payoff is well worth it – a cleaner, healthier workspace where you can focus on creating your best work. So don’t be afraid to get creative, experiment with new ideas, and always keep in mind the importance of industrial dust control simplified for a better working experience.

Frequently Asked Questions

What are the key components of an effective workshop dust collection system?

The key components of an effective workshop dust collection system include a powerful vacuum or fan, a robust dust collector, and a network of ducts and hoses to capture dust at its source – think table saws, sanders, and drill presses.

How often should I maintain and clean my dust collection system to ensure optimal performance?

Honestly, maintenance is key – I clean my dust collection system every 1-3 months, depending on usage. Check and empty the collector, inspect hoses for blockages, and give the filters a good clean. It’s a simple routine that’ll keep your system running smoothly and your workshop air clean.

Can a single dust collection system effectively manage dust and debris for multiple power tools and machines in my workshop?

Honestly, it depends on the system’s power and your workshop’s layout. A single, high-quality dust collection system can handle multiple tools, but it’s crucial to choose one with enough CFM to cover your entire space and ensure proper ducting to each machine.